I've learned a lot from other guitar builders over the years, and so this blog is a way for me to share my own build experiences and hopefully let others learn from my success and mistakes!

Älgen Catchup

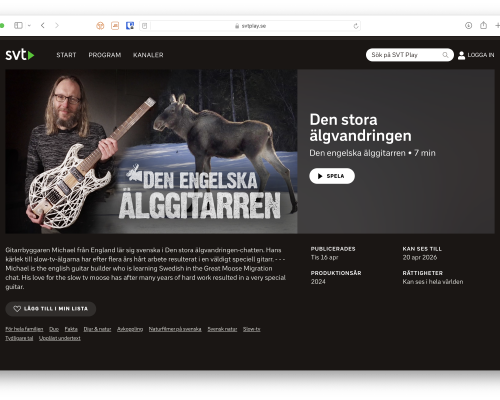

18 Apr 2024 - 3d-printing, älgen, markforged, svt

Catching up with Älgen: I end up on Swedish Public Broadcasting with the story of Älgen, and I go one level further into custom parts enabled by 3D-printing.

A month in the shop: wrapping up Delfinen

Workshop weeknotes: Delfinen becomes an instrument at last.

1 Mar 2024 - binding, delfinen, finishing, laser-cutting

Is this a guitar I see before me? Another weeknotes catching up with all that's happened to Delfinen since we last saw it, including it getting strung up for the first time.

Workshop Catch-up: Verkstaden

15 Feb 2024 - painting, spraying, verkstaden

Continuing the catch-up series: Verkstaden goes through the process of getting a gloss finish, and I end up making some costly mistakes along the way.

Workshop Catch-Up: Hästen

Workshop Catch-Up: Delfinen

A Couple of Weeks in the Shop

A Week in the Shop

31 Oct 2023 - delfinen, finishing, fretwork, hästen, verkstaden

Putting in the time: nothing new this week, just a week of getting on with the jobs I started previously in the workshop, with more staining, more oiling, and more fret-dressing and polishing.

A Week in the Shop

A Week in the Shop

15 Oct 2023 - correcting, deflinen, glue, hästen, staining, verkstaden

Last week we had a failed attempt to stain a guitar body, and this week we get to work saving the instrument from the rework pile.