A week in the shop

26 Nov 2018

I was under the weather for quite a bit of last week, so not a huge amount of progress to report on the guitar build front. The Clydesdale offset continues to move forward slowly: I’ve now finished the fretwork, and the next step is laser etching the logo oiling it. Fretwork is definitely something I need to find a way to improve on: although I felt the early stages went well, getting the frets buffed out was quite a lot slower than I expected. But it is there now:

For all the effort and my desire to avoid wenge for a few builds, it is looking lovely. Headstock etching, final sanding, and then oiling are the next stages.

After upgrading the CNC router last week I made a quick collet holder, as the old one no longer worked due to the new collet size. It was quite a quick job in Fusion 360 to design: it actually is pretty close to what I teach when I do my introduction to Fusion training course. Not long after I had the parts cut out on the CNC router and glued up, and the following day it was up and in use:

It’s little jobs like this that I really love about having all the tools in Makespace: you have an idea of something that’ll make your life easier, and a day later there it is in use. There’s a lot of focus in hack spaces on the esoteric things you can make, but I find this every day problem solving much more interesting.

On a related topic of making things that scratch a particular itch, I’ve been looking a little at sheet metal fabrication this week. With my new pedal setup I realised that although I have quite a nice pedal board, the way it does cable routing wasn’t quite right given some of the bigger pedals are larger than what the board was designed for, and perhaps I could design one that was better suited for my needs. The pedal board I have is made from a bit of folded metal with some nice wooden end-caps: the wooden end-caps I can easily make, but sheet metal is not something I’ve played with much before, and I felt it’s been a while since I pushed myself design ways, so I thought I’d give it a go.

Fusion 360 has a mode for sheet metal folding, which I had played with before a year ago when I tried modelling the pre-built chassis I bought for the amp I made. This time though I wanted to design something that didn’t quest exist yet, which was more fun, and I need to actually get it made rather than just worry about something already made, which is a different kettle of fish, as I have to think about construction practicality as well.

My initial mockup of the metal part for my new pedal board looks a little like this:

The main change between the pedalboard I have and the design I have here is just a tweak to how the cable slots are cut. I actually modelled it with rough replicas of my particular set of pedals in Fusion 360, so I know that they’ll fit perfectly. Beyond that it’s mostly what you’d expect to see in terms of a raised sloped surface with space underneath for cables and a power brick. In the back I found a socket and switch unit that’ll take a standard kettle lead which I can then forward to the Walrus Audio power supply I have that’ll sit under the board, making it easy to plug and unplug and turn on and off.

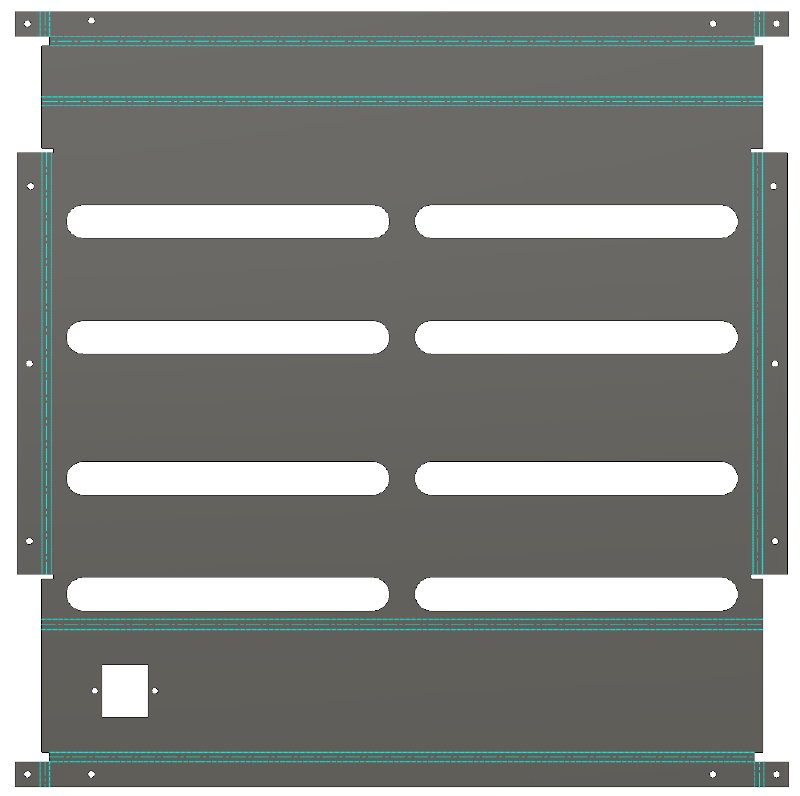

When folded out the sheet metal looks like this, which is what I’ll have to get someone to cut out and fold for me:

It’s really quite nice how Fusion lets you design in this way, making quite a complex task relatively simple for someone inexperienced in metalwork like myself. It has a stock set of bend radiuses etc for different metals, but it’ll be interesting to see how different fabricators will deal with my design.

I’ve sent it off to three different manufacturers for quotes, noting in the request what I thought might be problem areas with the design for fabrication just to enable them to complain if I’ve done something silly sooner rather than after I’ve spent a lot of money on getting it made. It’ll be interesting to see both how much it’ll cost to make and whether this easy to generate design actually cuts the mustard when given to a professional metal work person.