A week out the shop

4 Mar 2018

Not much shop action this week. I did go back into the shop to try fix the last bits of the amp left over from last week. I got everything fixed up except the neon power indicator light isn’t firing properly. I replaced it with a spare and same result, so either I’ve messed up or the pair I bought happen to be from a bad batch of indicators (though Occum’s Razor would imply the former rather than the latter :). Still, didn’t stop me annoying people in Makespace by firing it up and having a bit of a jam.

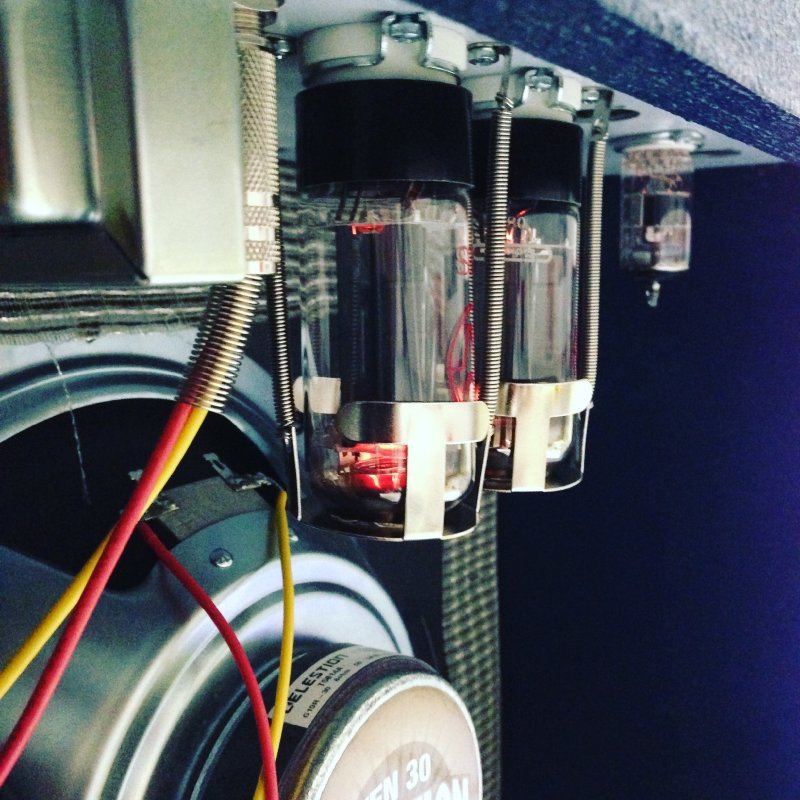

You can see the tubes are glowing nicely on the back:

Even though it’s just a 5 watt amp, it is loud! I didn’t crank it in Makespace out of respect to other using the workshop there, but at bedroom type levels it has a lovely clean sound with just a hint of break up. I look forward to dragging it into a practice studio in the very near future and opening it up properly.

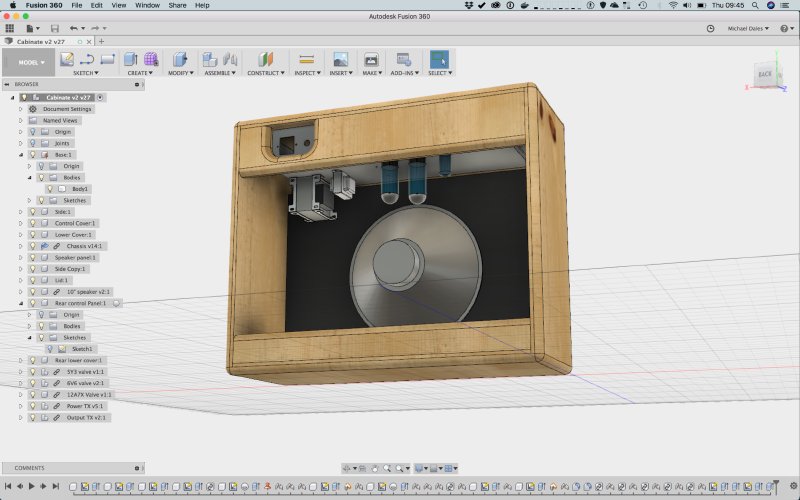

A couple of people have enquired if I’m going to build amps for people alongside my guitars. The answer there is a strong maybe, but I’ll have to gauge interest first. There’s a couple of reasons amps are harder to build than guitars, and it’s nothing to do with the actual construction part. Indeed, I’ve taken care with my amp design on the CAD side so that I can very quickly come up with new amp layouts (e.g., a 2x12 vs a 1x10, more controls, etc.) just by adjusting parameters in Fusion.

The first issue is, due to the very high voltages involved with a valve amp, I’d have to go through certification before I could sell them, which I’d have to do for each model I made. This makes it hard to do fully bespoke amps each time, but I could do a small set of designs with some minor variations (e.g., similar circuit but head vs combo would be counted as one design). But the basic point is I can’t just build them and flog them, I’d need to invest both time and money in the certification process, and at the moment I’m not sure I offer much over any others building custom amps. The second is the cost for me of building amps to a specification that makes me proud of them vs what the going rate seems to be for a small practice/first gigging amp makes me think very few people would pay say a grand for a 5W amp, even if it was lovingly hand made out of top quality bits.

But, if you’d like to add your voice to those asking if I’m going to make them so that I can work out if its worth the investment in certification, let me know. For now I’m going to settle for this, and perhaps later in the year build a 15W gigging amp based of a Fender Deluxe type circuit. But for now, I have some guitars to build…

The prototype guitar offer I made a few weeks ago has now properly closed, with deposits in, and two guitars locked in to be made (it did look like three, but alas one got away for now). I started ordering bits, most importantly the wood so I can get started on these. The wood for these is coming from Exotic Hardwoods UK Ltd, who have a wonderful range of materials for guitar building. Once these are in I can get gluing and machining the wood into rough shape. I was hoping the wood would have arrived, but the disruption caused by the snow has stopped deliveries getting through as quickly.

Both the prototypes in the end are for offset guitars rather than teles, which is not what I set out to do, but I’m quite excited about this. Both will be based on a Fender Mustang, which is a short scale length guitar, and one of the cheaper guitars that Fender offers, which means if you want a nice high quality Mustang you need to go custom. From a builder’s PoV they’re sufficiently close to a t-style guitar that what I wanted to achieve from the prototype series in terms of workflow still holds. So I get to make something unique for both customers. Here’s an early prototype rendering of one of the guitars, which will be a thinline model:

That’s about it for this week, as I’ve mostly been waiting for bits and doing non-guitar contract work, but looking forward to being back in the shop in the coming weeks!