A frustrating start to the new year

Published 8 Jan 2019

I’ve been putting this week notes off as it’s been a frustrating week, but the point of these notes is to show the good with the bad, so let’s get to it.

As discussed last week, having diagnosed the latest fault with the CNC router down to the fact that it didn’t like one particular file I gave it, despite being valid, I generated the same tool path with slightly different layer heights and when I tested that on air, it all worked fine. Thanks CNC Router.

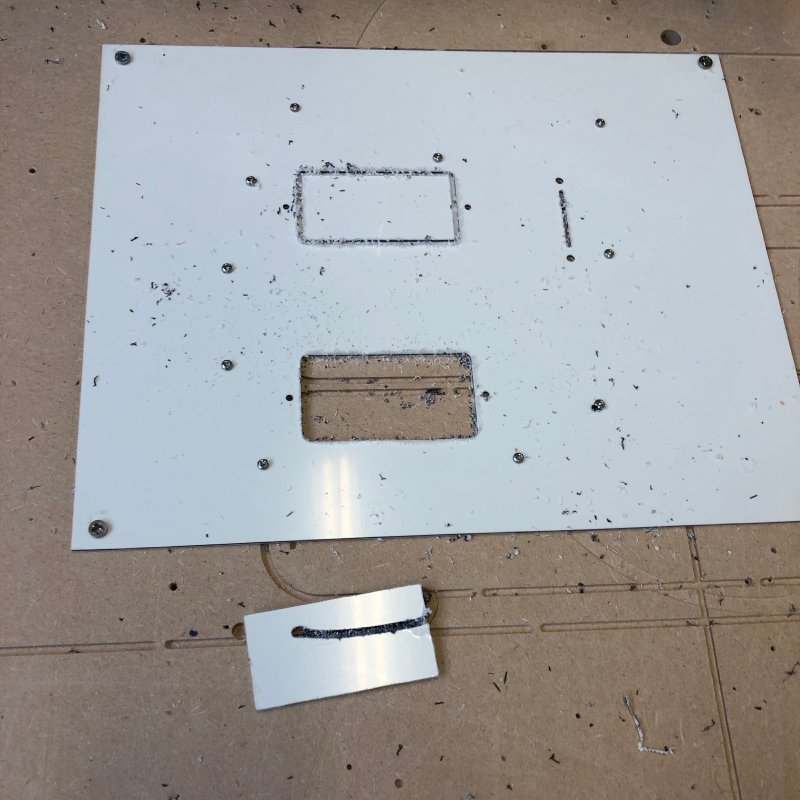

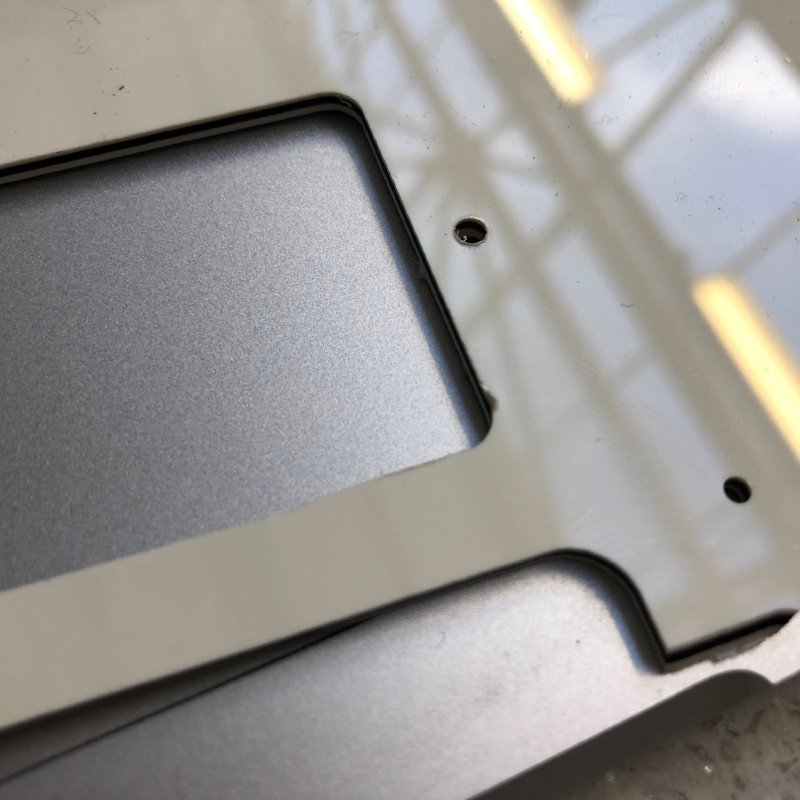

So, I sat down to route the pick guard once again, but this time I had a more conventional failure, which left me with an almost perfect pick guard but with an annoying ding in it. When cutting out the holes for the pickups in the pick guard the the piece to be removed, which should have been secured by double sided tape on the rear, came loose, which then hooked on the router bit and managed to get in the way:

This caused the bit to deflect, making the edge there slightly less straight than it should be:

The pick guard is otherwise fine, but the professional in me sees this as unacceptable to ship.

So another failure, and I’m beginning to feel very cursed right now. The fix here is to not rely on the tape alone - I should have put a couple of screws in the bit that came loose - but for before now I’d managed to get away with it just using tape. To top it off, before I got time to cut it out again, the CNC Router pendant’s USB port broke, so now I’m without CNC Router until we replace it.

As the kids say, FML.

All in all, a frustrating week, which is why I didn’t really want to write up these notes. I’d set myself the goal to finish The Clydesdale by xmas, then by new year, and each time I hit yet another problem.

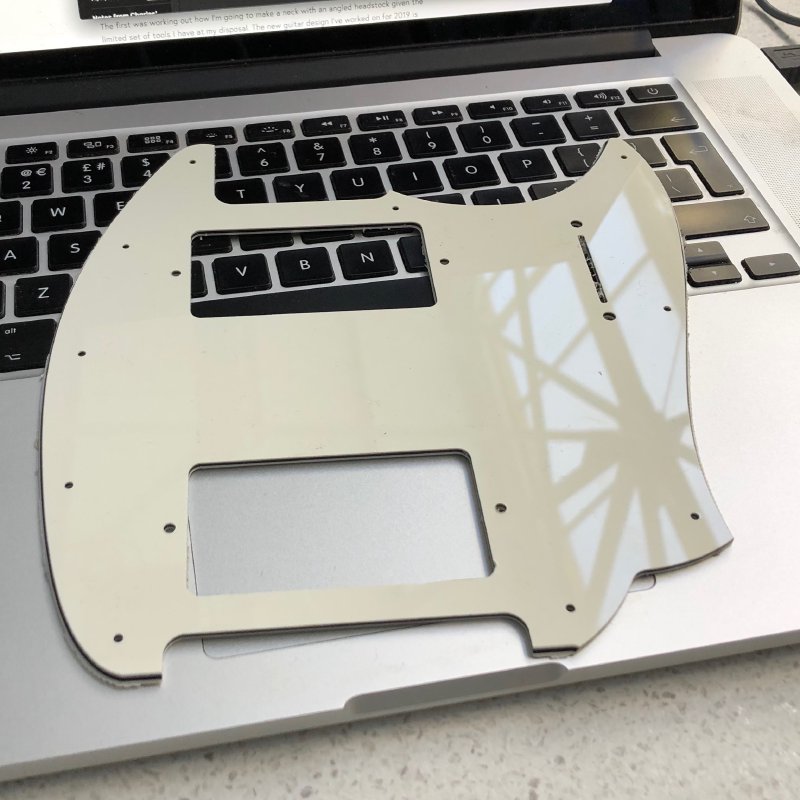

However, rather than just stop, I do have a pick guard that is the right shape and size and has the right holes in the right place, so what I’ll do this week is finish the rest of the guitar with this pick guard and then when the CNC Router starts working again I’ll cut another.

And when will the CNC Router be fixed? Well, Makespace has ordered two new controllers to try, and they’ll turn up mid Jan, so fingers crossed one of those will make us happy.

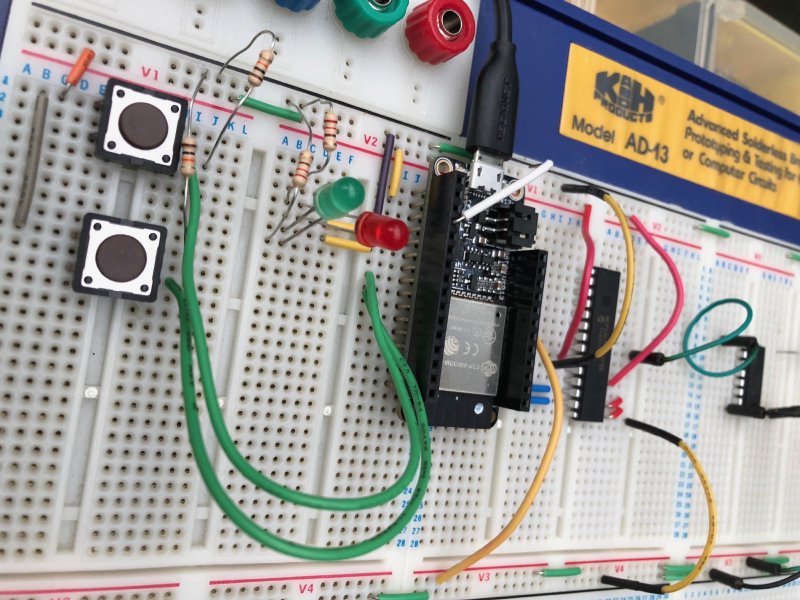

Given the frustration and given I was still trying to spend the new year at home whilst my other half was around more, I did some more playing with electronics. I actually did two years of electronics at university (over 20 years ago for those counting), but have not used it since (whilst I have done on-chip design since then, that’s a very different kettle of fish to playing with capacitors and resistors).

My little project to help me relearn electronics is to make myself a pedal switcher, as at 6 pedals I have enough in my chain now that with it all “off” I still have a notable change in tone (doesn’t help that three of my pedals are buffered).

Thus, thanks to the advice of my friend Jason (who I helped with his Nixie Clock back in the summer), I got myself an Adafruit HUZZAH32 microcontroller and a bunch of other parts to let me prototype the bits I’d need for a switcher: an I/O expander chip to let me control more things than the HUZZAH32 will control directly, some latching relays, and some transistor arrays to let me power those.

Early days, bit slowly getting there with the design, here I’ve got everything hooked up bar the relays as they don’t fit onto the breadboard here, I need to make a small board with stripboard with those on.

A nice distraction from the woes in the workshop.

So, with 2019 arriving and the guitar building in 2018 not having gone anything like as well as I’d hoped, I think I need to reset my expectations. I tried to push along with the guitar building with the assumption that I could do a lot on the CNC Router and that just isn’t the case. Even with a fully working CNC Router I think it’s not a tool designed for quick one-off productions: either it’s something you labour over a lot time wise for a one-off that can be made no other way, or you want to do some test pieces and then never change your design and make multiples of them. But I’m not making enough guitars that I’ve hit that point, so I need to trying to use production techniques that suit the fact I’m making one off guitars for people or one-off test guitars to get me to that small volume production place.

I had designed some ambitious guitars for this year, which used both carved tops and angled headstocks, but I think committing to those would be foolish at this point, they rely too much on the CNC Router as a tool for making the guitar not just templates to let me build guitars by hand. Instead, at this point, I want to be making templates and using a hand router to generate the guitars, and designing to match a more traditional workflow given what I have access to. I just want to make some simple guitars this year that let me regain momentum and having the satisfaction of shipping.

I’ll finish these two offsets, and then I’ll switch to making a sort of Junior version of the guitars I’d hoped to make for 2019: so flat tops, hand carved contours, and no angled headstocks. On one had I’m again frustrated, as in my head is this guitar I want to make and play, and now that’s a 2020 project, but on the flip side I just want to make guitars and see people play them, and that’s more important. So here’s to more wood being turned into music this year.